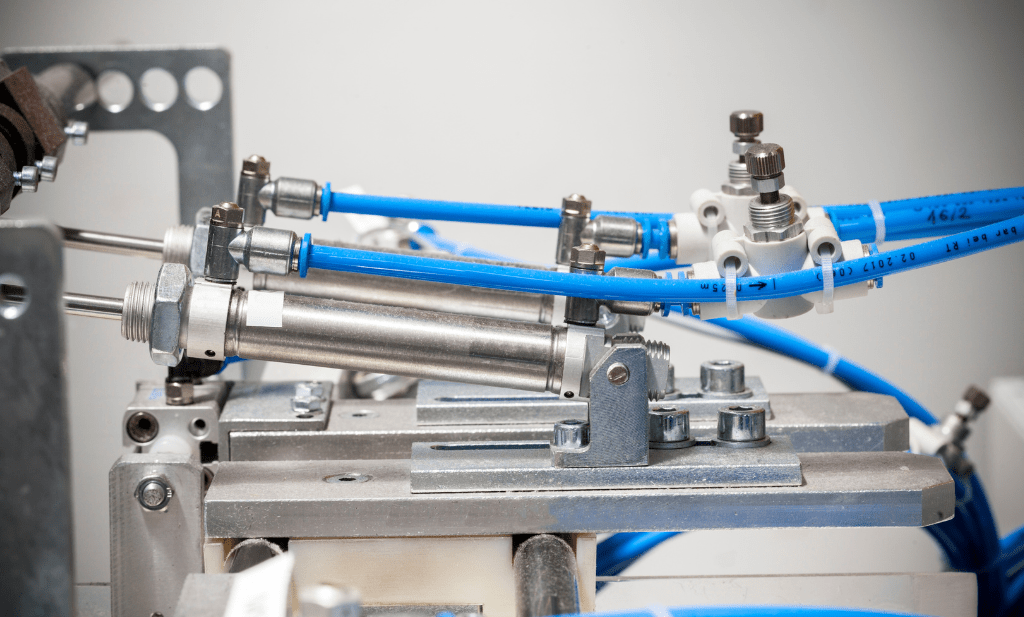

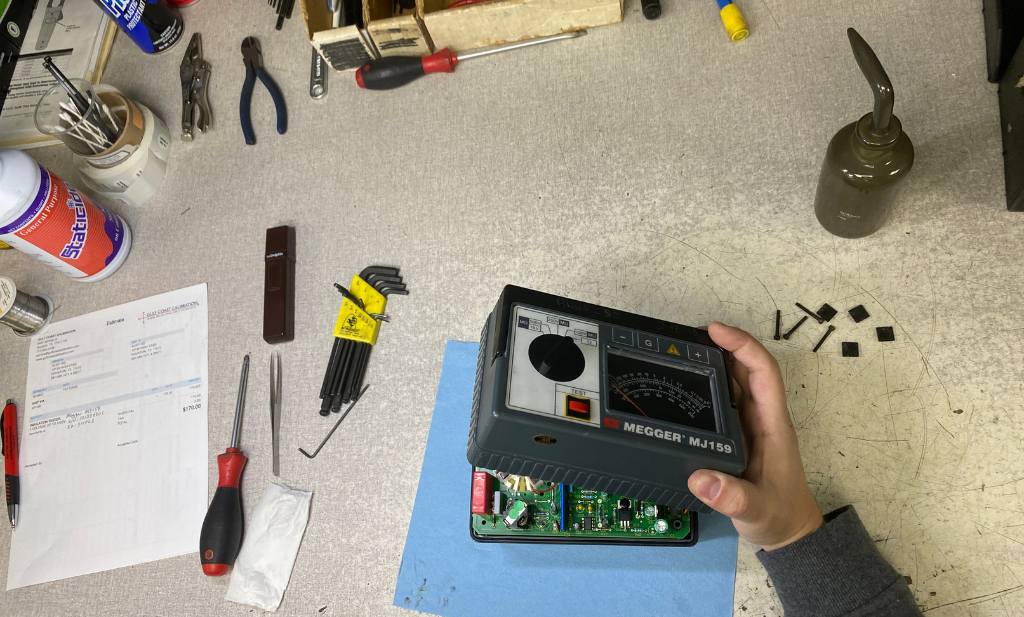

Hydraulic vs. Pneumatic Pressure in Calibration

When considering how to build or enhance a calibration program, there is a lot to consider. Especially when dealing with a wide range of pressure ranges – both high and low – when gas and liquid are employed in the