Rubber Glove Testing

Gulf Coast Calibration is a trusted name in electrical high voltage testing, serving the Texas Gulf Coast region with our rubber goods testing laboratory based in Houston.. We have one of the quickest turnarounds of rubber goods testing which, in most cases, is ten days. Each rubber good that is tested is washed, tested, hand and visually inspected and dated. Each employee of Gulf Coast Calibration puts pride in their work and the safety of our clients is the first and foremost most important goal.

Our Rubber Goods Testing Capabilities include:

- Rubber blanket & mat dielectric testing

- Electrician’s insulating glove dielectric testing

- Lineman’s glove & electrical PPE dielectric testing

- High voltage & low voltage glove dielectric testing

- Rubber line hose & cover-up dielectric testing

- Rubber sleeve & overshoe dielectric testing

- Dielectric testing of salisbury electrical glove/Chance/Novax rubber gloves.

Rubber Glove Testing

Gulf Coast Calibration is a trusted name in electrical high voltage testing, serving the Texas Gulf Coast region with our rubber goods testing laboratory based in Houston.. We have one of the quickest turnarounds of rubber goods testing which, in most cases, is ten days. Each rubber good that is tested is washed, tested, hand and visually inspected and dated. Each employee of Gulf Coast Calibration puts pride in their work and the safety of our clients is the first and foremost most important goal.

Our Rubber Goods Testing Capabilities include:

- Rubber blanket & mat dielectric testing

- Electrician’s insulating glove dielectric testing

- Lineman’s glove & electrical PPE dielectric testing

- High voltage & low voltage glove dielectric testing

- Rubber line hose & cover-up dielectric testing

- Rubber sleeve & overshoe dielectric testing

- Dielectric testing of salisbury electrical glove/Chance/Novax rubber gloves.

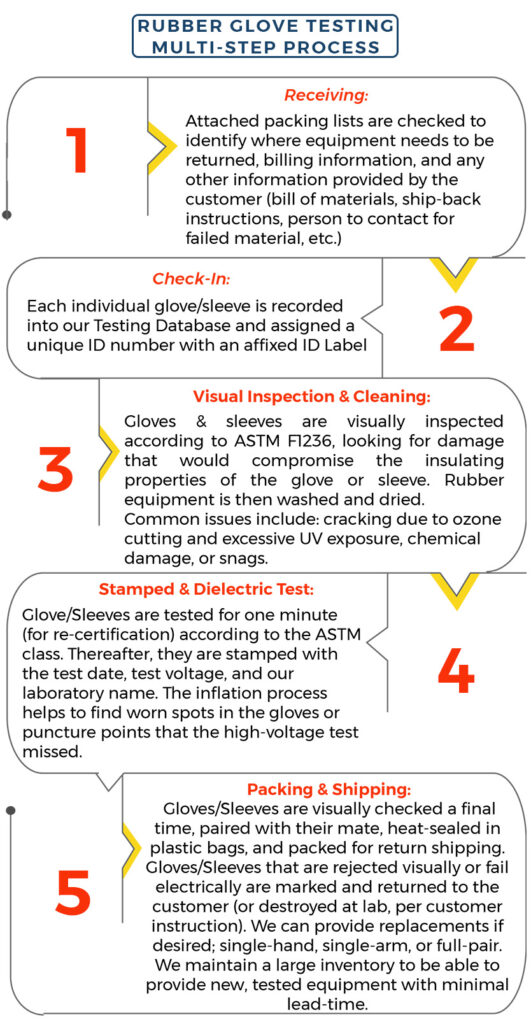

All Gloves and sleeves for re-test go through a multi-step process.

How Often Should You Test Your Rubber Glove?

The Occupational Health & Safety Administration (OSHA) regulates how people can work on high and low voltage electricity. You can read the OSHA standard 1910.137 table of contents by clicking here. OSHA’s regulations are based on the standards issued by ASTM International (Originally known as the American Society for Testing and Materials) an organization whose members are made up of professionals from a number of industries, including the electrical industry.

The ASTM standard for rubber goods states that rubber gloves shall be electrically tested at least once each six months by a qualified testing lab after they have been used. Sleeves must be electrically tested every twelve months. Companies and unions often shorten that time frame to better protect their workforce. For example, companies may choose to test every 30 days or 90 days, or whatever they choose within the ASTM guidelines. The standards also state that complete records must be kept of all such tests and dates of issue.

Below are industry standards that provide additional guidance on rubber goods testing:

- OSHA 1910.137 – Must be electrically tested before first issue and every six months thereafter.

- OSHA 1910.268 (Tele-com) – Natural rubber insulating gloves must be electrically tested before first issue, twelve months after first issue and every 9 months thereafter.

- ASTM D120 Rubber Insulating Gloves

- ASTM D1051 Rubber Insulating Sleeves

- ASTM F496 In-Service Care of Gloves/Sleeves

- ASTM F1236 Guide for Visual Inspection of Electrical Protective Rubber Products

Rubber blankets, must be electrically tested at least once each year after they are checked out for use, and complete records must be kept of all such tests and dates of issue. Rubber protective equipment not checked out for use within one year must be re-tested before being issued. But, like the standard for gloves and sleeves, many companies and unions shorten this timeframe. ASTM has not set a mandated time standard for testing line hose and hoods. ASTM does mandate a test for line hose and hoods if there is suspected damage. Then, the products should be tested by a qualified lab that meets ASTM standards such as American Safety’s to test the potentially damaged goods.

Please click on the Request a Quote button below or call 713.944.3139 for all your Rubber Glove Testing needs.