- November 21, 2023

- by Emmanuel

- Calibration

Hot Sticks Safety and Accuracy

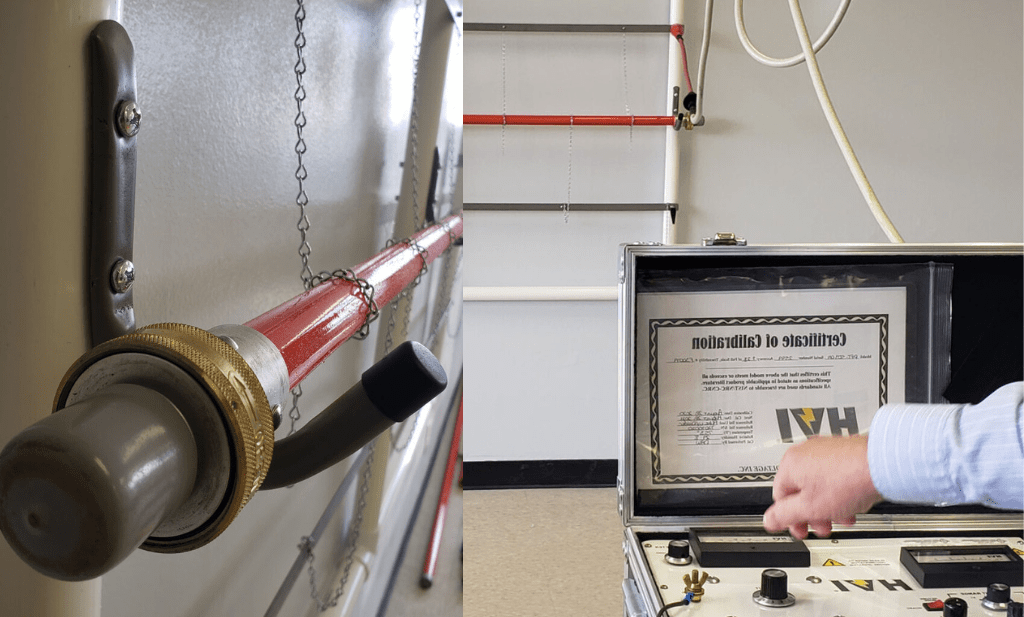

Hot sticks are essential tools for electric utility workers who perform live-line work on energized high-voltage power lines. They are insulated poles, usually made of fiberglass, that allow workers to operate various devices on the line without exposing themselves to electric shock. However, hot sticks are not immune to damage, wear and tear, or environmental factors that can compromise their insulation and mechanical properties. Therefore, it is crucial to inspect, test, and calibrate your hot sticks regularly to ensure their safety and accuracy.

Inspection

Before using a hot stick, you should always inspect it visually for any signs of damage, such as cracks, chips, dents, burns, or contamination. You should also check the hardware, such as nuts, bolts, clamps, and springs, for any looseness, corrosion, or deformation. If you find any defects, you should not use the hot stick and report it to your supervisor for repair or replacement.

You should also inspect your hot stick after each use and clean it with a mild detergent and water. You should avoid using any solvents, abrasives, or harsh chemicals that can damage the fiberglass or the protective coating. You should also store your hot stick in a dry and cool place, away from direct sunlight, heat sources, or sharp objects.

Testing

In addition to visual inspection, you should also test your hot stick periodically for its electrical and mechanical performance. Electrical testing involves applying a high voltage to the hot stick and measuring the leakage current or the dielectric strength. Mechanical testing involves applying a bending or tensile force to the hot stick and measuring the deflection or the breaking point.

There are different standards and methods for testing hot sticks, depending on the type, length, and application of the tool. For example, ASTM F711 specifies the requirements for hot sticks used in electric power generation, transmission, and distribution. OSHA 1910.269 specifies the safety practices for workers who perform live-line work. You should follow the relevant standards and methods for your hot stick and use the appropriate equipment and procedures for testing.

Calibration

Calibration is the process of comparing the output or the measurement of a hot stick to a known standard and adjusting it if necessary. Calibration ensures that your hot stick is accurate and reliable for its intended use. For example, if you use a hot stick to measure voltage, current, or resistance on a power line, you need to calibrate it against a reference meter or a traceable source.

Calibration should be performed by a qualified and accredited calibration laboratory, such as Gulf Coast Calibration, that has the expertise and the equipment to calibrate your hot stick according to the industry standards and specifications. You should calibrate your hot stick at least once a year or more frequently, depending on the frequency and the severity of use, the environmental conditions, or the manufacturer’s recommendations.

Conclusion

Hot sticks are vital tools for electric utility workers who perform live-line work on energized high-voltage power lines. They provide insulation and mechanical strength to protect workers from electric shock and to operate various devices on the line. However, hot sticks can deteriorate over time and lose their safety and accuracy. Therefore, it is essential to inspect, test, and calibrate your hot sticks regularly to ensure their optimal performance and reliability.

Let Gulf Coast Manage Your Calibration Schedule.

If you need professional and quality calibration services for your hot sticks or other electrical tools, contact Gulf Coast Calibration today. We are an ISO 17025 accredited calibration laboratory that offers a wide range of calibration and testing services for electrical, temperature, pressure, dimensional, and other instruments. We have state-of-the-art equipment and experienced technicians who can calibrate your hot sticks and other tools according to the industry standards and specifications. We also offer fast turnaround times, competitive prices, and excellent customer service. Contact us today and get 10% off your first calibration or testing service with us!

Call us to discuss your calibration, test or repair needs at:

713.944.3139.