- August 3, 2023

- by Emmanuel

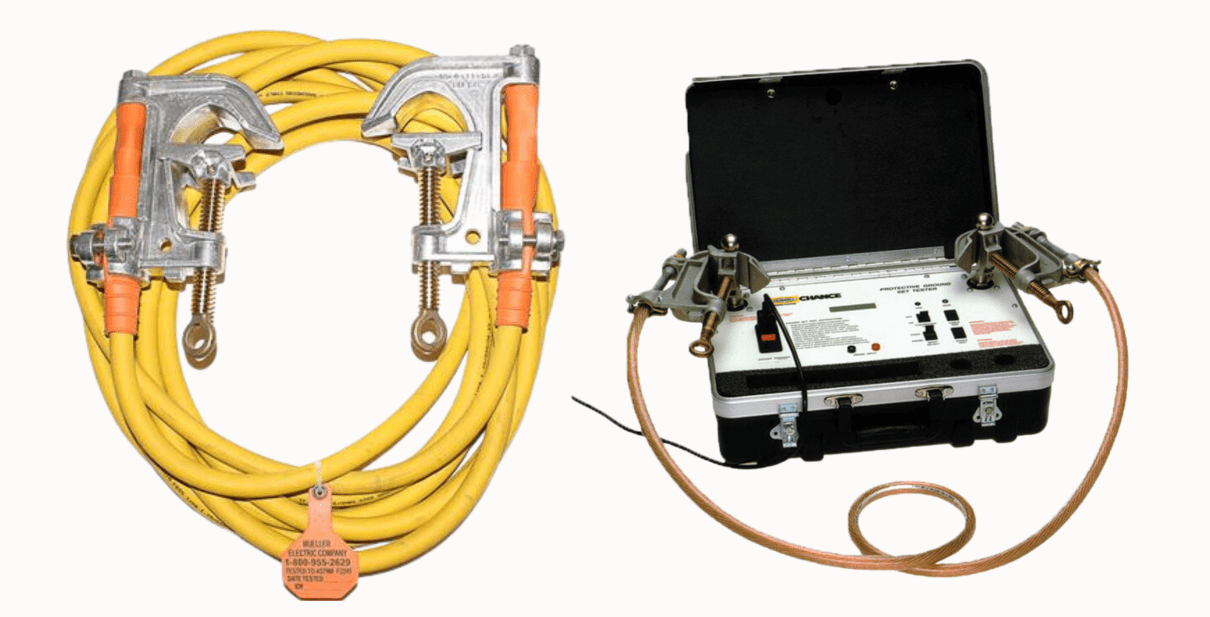

- Grounding Cable Testing

Ground cable testing is a crucial process in various industries to ensure the safety and efficiency of electrical systems. Whether you work in construction, manufacturing, or any other field that relies on electricity, understanding the importance of ground cable testing is essential. In this blog post, we will explore what ground cable testing is, why it is necessary, and how it is conducted.

What is Ground Cable Testing?

Ground cable testing is a method used to assess the integrity of the grounding system in electrical installations. The grounding system provides a safe path for electrical currents to flow into the ground, preventing electrical shocks and equipment damage. By testing the ground cables, professionals can identify any faults or weaknesses in the system.

Why is Ground Cable Testing Necessary?

Ground cable testing is necessary for several reasons. Firstly, it ensures the safety of personnel working with electrical equipment. Faulty or damaged ground cables can lead to electric shocks, which can be life-threatening. Secondly, it helps protect equipment and machinery from electrical surges. Grounding systems divert excess electrical currents away from sensitive equipment, preventing damage and downtime.

Additionally, ground cable testing is crucial for compliance with industry standards and regulations. Many regulatory bodies require regular testing to ensure that electrical systems meet safety requirements. By conducting thorough ground cable testing, businesses can avoid penalties and legal issues.

How is Ground Cable Testing Conducted?

Ground cable testing involves several steps to assess the integrity of the grounding system. The process typically includes the following:

- Visual Inspection: A visual examination of the ground cables and connections is conducted to identify any visible damage or deterioration.

- Resistance Measurement: Using specialized equipment, the resistance of the ground cables is measured. This helps determine if the cables can effectively carry electrical currents.

- Continuity Testing: Continuity testing is performed to ensure that the ground cables are properly connected and that there are no breaks or interruptions in the path.

- Ground Fault Testing: This test is conducted to detect any ground faults in the system. It helps identify if there are any unintended paths for electrical currents.

By following these testing procedures, professionals can accurately assess the condition of the ground cables and take necessary actions to rectify any issues.

Conclusion

Ground cable testing is a critical process that ensures the safety, efficiency, and compliance of electrical systems. By conducting regular testing, businesses can prevent accidents, protect equipment, and meet industry standards. If you work in an industry that relies on electricity, make sure to prioritize ground cable testing to maintain a safe and reliable working environment.

Related resources

Call us to discuss your calibration, test or repair needs at:

713.944.3139.